Description

-

Product Description

A diamond grinding plate is an advanced tool used in surface grinding processes, especially on hard metals like cast iron, ductile iron, and SG iron. These plates are embedded with diamond particles, known for their unmatched hardness and wear resistance, ensuring superior grinding performance, extended tool life, and precision.

| Parameter | Details |

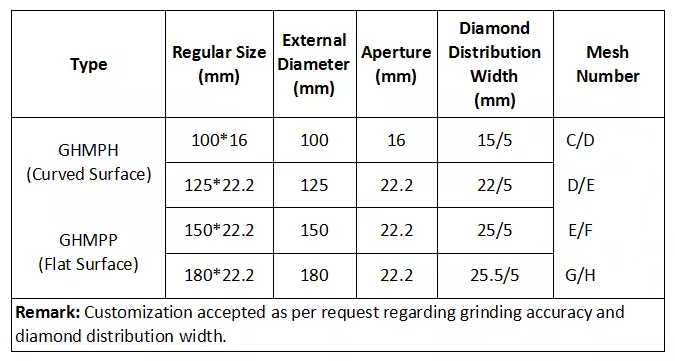

| Plate Diameter | e.g., 100 mm,125mm, 150 mm,180mm, 230mm, 250mm,300mm, 350mm, 400mm, 600mm customize also available. |

| Bond Type | Fusion bond, etc. |

| Working Surface | e.g., Single-sided or double-sided |

| Thickness | e.g., 2.0 to ,50mm |

| Segment Configuration | Zigzag, flat, turbo pattern |

| Weight | Varies based on size and thickness |

| Operating Speed | RPM range (e.g., 2830-10000 RPM) |

| Attachment Mechanism | Velcro, Magnetic, or Bolt-on |

| Cooling Mechanism | Wet or dry grinding capability |

Q1: How do I choose the right diamond grit size?

A1: The choice of grit size depends on the application. Coarser grits (e.g., 30/40) are ideal for fast material removal, while finer grits (e.g., 50/60) are better for finishing.

Q2: Can I use this grinding plate for both wet and dry grinding?

A2: Yes, most diamond grinding plates are designed for both wet and dry grinding. However, wet grinding is recommended for extended tool life and better surface finish.

Q3: What is the lifespan of a diamond grinding plate?

A3: The lifespan depends on the material being ground, the operating conditions, and the frequency of use. Typically, diamond plates last longer than conventional abrasives when used properly.

Q4: Can it be used on non-metallic materials?

A4: Diamond grinding plates are generally designed for metallic surfaces, but some versions may work on non-metallic materials such as ceramics.

Q5: What is the difference between metal bond and resin bond diamond plates?

A5: Metal bond diamond plates are more durable and better for heavy-duty grinding, while resin bond plates offer a smoother finish and are typically used for light to medium grinding.